- Howie Fenton

- |

- May 10, 2021

As we continue to prepare for a recovery from the pandemic and rebuild our business, we have to recognize that while commercial companies have begun to recover, in-plant's business usually lags behind commercial companies for several months. This does not mean that in-plants are laggards, but that volume growth and declines in in-plant service providers tend to be delayed compared to commercial companies. In addition, it means that the recovery for in-plants will be slower to develop. This is the first of two articles discussing the costs and production challenges of accepting e-mail orders and how Web to Print solutions can contribute to your recovery beyond accepting online orders.

In a recent webinar, Andy Paparozzi from the PRINTING United Alliance found that over half (52%) of commercial graphic and sign producer companies predict that their businesses will improve in the months ahead. This is noteworthy because it is the most ambitious prediction since the beginning of the pandemic. But for many in-plants, especially Universities, September looks like a good target to relaunch the business.

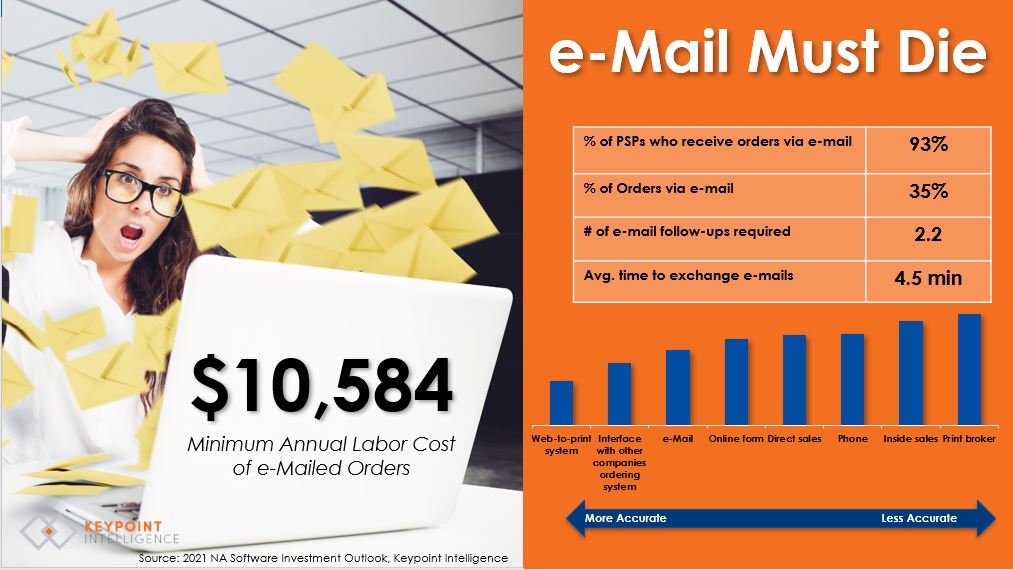

Ryan McAbee, the Director of Production Workflow at Keypoint Intelligence (KPI), recently published the 2021 North American Production Software Investment Outlook: Exploring the value of workflow automation and print e-commence. While the title is a mouthful, the main point is simple; there is a high cost for companies accepting orders from e-mail instead of automating the front-end processes with Web to Print software.

One of the key findings of the research was "Job onboarding remains a significant obstacle for end-to-end automation since most PSPs still rely on e-mail as the primary method for customers to place orders and upload artwork. The manual processes associated with e-mail are costing PSPs a minimum of $10,584 per year."

Accepting E-mail Orders Costs More

At first glance, you may be asking, "How does accepting jobs by e-mail cost over $10K?." It is simple, really; it is all about the cost of labor. Every time a customer e-mails an order, there is a time associated with working the original e-mail and subsequent e-mail communications. KPI found that on average, over 90% of companies receive orders via e-mail; of those companies, about one-third of all orders are e-mailed; for every e-mailed order, there are two or more e-mails, and the time required to create each e-mail is about 5 minutes. Once you figure out the time, you multiply that by the cost associated with the CSR.

As you can see in the graphic, this can result in about $10,500 of labor.

Four Other Ways Web to Print Software Helps Reduce Costs

You may need to handle the increasing order volume during the recovery with fewer production staff or a reduced budget. In addition to driving down the time and inefficiencies of e-mail ordering and interactions, there are other ways to save your operation time and labor costs by using Web to Print software. Let's take a look at four ways this workflow software can help.

- Eliminate job tickets. One time-consuming aspect of traditional print production workflows is the job ticketing process. Filling out job tickets can take between 10 – 40 minutes, depending on the complexity of the order. Using a Web to Print solution can eliminate or reduce that time. In addition, reorders are faster and easier for customers and staff.

- Templated solutions. For many in-plants, stationery products such as business cards, letterhead, and envelopes make up a large percentage of orders. Typically we find that stationery products make up 20%-50% of the total number of orders. Some in-plants utilize designers to customize these products manually. This is very time-consuming and easily remedied with online templates. A business card template is easy to set up and allows customers to fill in their information and eliminate in-plant staff intervention. Templates can also be used for signage, fundraising letters, postcards, and newsletters.

- Brand consistency. Another advantage of using templates is that it ensures brand consistency. You don’t have to worry about customers changing the logos or taglines under them. Furthermore, suppose you have logos created to take advantage of custom color mixes that allow your digital press to more accurately print your logos. In that case, this is automatically done as opposed to manually replacing logos in customer files. This could help you become best friends with legal and anyone who serves as the brand police.

- Preflight Issues. When you study print production workflows, you find many reasons why delays and mistakes are made. Many can be traced to customer files and the inability to identify issues early enough. When a customer e-mails a file, it can take hours or days before someone looks at it and finds problems with fonts, colors, or the paper size selected. If the job requires a fast turnaround time, you may not have the ability to request changes from the customer and have to fix the problems. With e-mailed files, this creates the need to preflight and repair files. But some Web to Print solutions like RSA's WebCRD offer the ability to check for missing fonts, low-res pictures, and incorrect color selections.

Summary

By reducing the high cost of e-mail ordering and taking advantage of other Web to Print capabilities such as eliminating manual job ticketing, using templates, and identifying preflight issues earlier in the process, it's easy to see why killing e-mail and increasing productivity matter in your recovery.

In our next article, we will discuss other cost savings associated with Web to Print and how that can increase your savings by orders of magnitude.

How Much Does Killing E-Mail Orders Benefit You?

Find out how much killing e-mail orders and using the Web to Print features we discussed here can benefit you. Contact me or RSA to find out.