- Howie Fenton

- |

- June 20, 2017

This is the second of three blogs that address how to create a strategy to justify your existence and prove the value of the in-plant, corporate or in-house print center. In the first blog, we talked about measuring performance. In this blog, we are discussing bench-marking performance.

Three Types of In-plant Managers

There was a time when in-plant managers took comfort in the fact that their long-term relationship with their supervisor and personal relationships with management insured continued work. While there are still some managers that can say that, they are in the minority. Other managers report they have needed to defend their in-plant's existence one or more times in the last five years. For many going through a scrutinized evaluation of performance, it can seem like a battle. While I don't suggest creating an adversarial relationship when under the microscope, it is not a bad way of approaching day-to-day work. Be prepared to battle the allegations of the outsourcers and facilities management companies. Be prepared to fight their data with your data. There is a third group of managers who dislike the sudden requests to defend and instead have built processes to proactively maintain numbers to prove their value.

Sales Per Employee Ratio (SPE) is Only One Benchmark to Consider

Arguably the most common metric of performance is the sales per employee (SPE) ratio. It is easy to calculate by simply dividing the number of staff into the dollar volume of sales. It is commonly used in both commercial printing and in-plants, but I don't consider it alone as a strong predictor of leadership.

Why? Because I have worked with some in-plants whose SPE was considered low (less than $110K/person) that were world class and others that appeared as leaders (over $140K/person) that were outsourced. SPE ratios are different for different types of companies such as: graphic arts in-plant printers, quick printers, mailing service providers, and transactional in-plant printers. For example, the industry average for a commercial printer may be $135K/employee but it may be $180 K/employee for a transactional in-plant printer. SPE is still important, but with a few caveats. First it is most effective with similar types of companies with similar applications. Second, I believe it is only one of many benchmarks that need to be considered together. For in-plants, other benchmarks include: competitive pricing, turnaround times or SLA (service level agreements), percentage waste, cross-trained staff, and net promoter index.

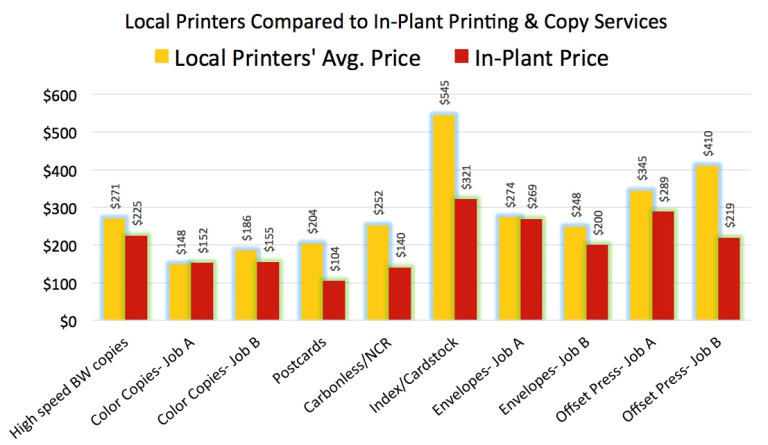

For in-plants that charge back for services, I believe that competitive pricing may be more important than the other benchmark measures. The problem, however, is that most in-plants are not prepared to defend their costs because: they don't update their costs often enough, only occasionally check prices (but claim to check it more frequently), and don't document or act on the results. In contrast, leading in-plants update costs every year, check external pricing every weekly, document their results and meet with staff to discuss how to get costs more in line.